进口自力式压力调节阀是不需要任何外加能源,利用被调介质自生调节的执行器产品。该产品最大特点,能在无电、无气的场所工作,同时又节约了能源,压力设定值在运行中可随意调整。采用快开流量特征,动作灵敏、密封性能好,因而它广泛应用于石油、化工、电力、冶金、食品、轻纺、机械制造与居民建筑楼群等各种工业设备中各种气体

用途和适用范围 Feature and application

自力式压力调节阀(以下简称压力阀)是一种无需外来能源而只依靠调介质自身的压力变化进行自动调节压力的节能型产品.具有测量、执行、控制的综合功能。广泛适用于石油、化工、冶金、轻工等工业部门及城市供热、供嗳系统。本产品可用于非腐蚀性(最高温度350℃)的液体、气体和蒸汽等介质的压力控制装置。

Pressure self-regulating valve (herein after referred to as pressure valve), a energy saving product, regulates pressure automatically without external energy supply. Pressure valve is used for pressure control device of non-corrosive liquid, gas and steam medium etc. that has integrated function of measure, performance and control. Pressure valve finds us in the field of petroleum, chemical industry, metallurgy and light industry and city heating system etc..

结构及工作原理 Structure and working principle

产品结构 Structure

本产品为直接作用型自力式压力调节阀.由阀体、阀座、阀芯部件、阀盖、顶盘、上、下膜盖、膜片、弹簧、调节螺母等零部件所组成。

其具体结构参见图la,图lb、图lc、图ld所示:

Pressure valve is of direct action type, which is composed of body, seat, core parts, bonnet, highest quotation, diaphragm, spring, adjusting nut and upper and bottom diaphragm cover etc..

The specific structure sees chart 1a, 1b, 1c and 1d.

工作原理 Working principle

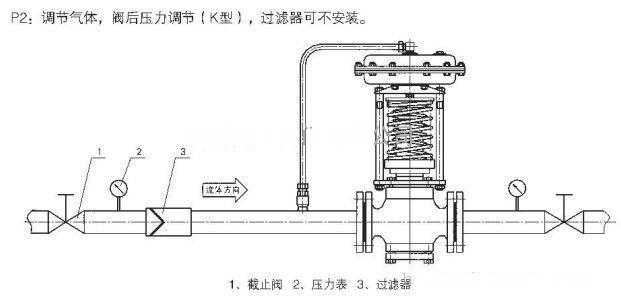

(I)作阀后压力调节时的工作原理:(见图la)

工艺介质的阀前压力Pl经过阀芯、阀座的节流后,变为阀后压力P2。P2经过控制管线输入执行器的下膜室作用在顶盘上.产生的作用力与弹簧的反作用力相平衡.决定了阀芯、阀座的相对位置.控制阀后压力。当阀后压力P2增加时.P2作用在顶盘上的作用力也随之增加。此时.顶盘的作用力大于弹簧的反作用力.使阀芯关向阀座的位置.直到顶盘的作用力与弹簧反作用力相平衡为止。这时.阀芯与阀座之间的流通面积减少.流阻变大.从而使P2降为设定值。同理,当阀后压力P2降低时.作用方向与上述相反.这就是阀后压力调节时的工作原理。当需要改变阀后压力P2的设定值时.可调整调节螺母8。

(1)The working principle of regulating the back of valve’s pressure :(see chart 1a)

After being throttled by core and seat, P1 becomes P2.(P1 stands for the front of valve’s pressure and P2 stands for the back of valve’s pressure.)Getting through bottom diaphragm room, P2 acts on the highest quotation and creates acting force. The acting force keeps its balance with reacting force of spring, which decides the relative place of core and seat and controls the back of valve’s pressure. When P2 increases, the acting force is also increasing. Here, the acting force is bigger than the reacting force, which made the core close to the seat until balance. And the circulation area between core and seat decreases and flow resistance increases, thereby P2 fell to the setting value. Also, when P2 decreases, the acting force direction is contrary.

When P2 `s setting value needs to be changed, you can regulate the adjusting nut 8.